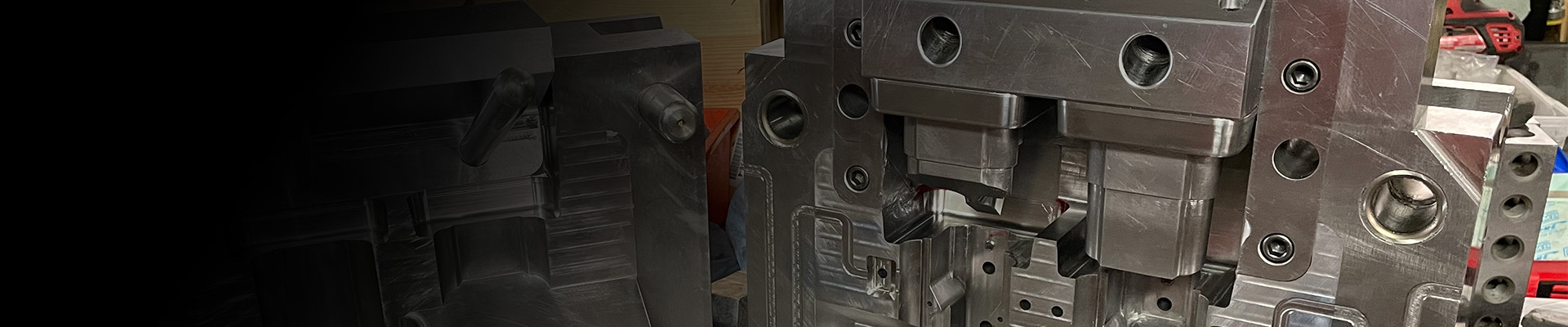

How Mold Repair Works

Injection molding is a common manufacturing process used to produce plastic parts. However, when molds become damaged, it can be difficult to maintain quality and efficiency in production. From cracks to broken cores, injection mold repair and modification is essential for keeping your molds in top condition.

Mold Repair Process

Whether you need to repair or replace an existing mold, understanding the process and capabilities of a reliable service provider can help you make the best decision for your project. Here we discuss the intricacies of injection mold repair and modification.

Mold repair is a complex process that requires expertise and experience to ensure the longevity of an injection mold. The first step in the repair process is to inspect the damage and design a solution that will least affect the lifetime of the mould. After this, repairs are often completed within five days or sometimes even over the weekend if production downtime needs to be avoided.

Accel Precision can provide both preventative maintenance and timely repairs; we work with various types of materials, such as glass-filled materials, for a reliable molding process.

Depending on the Extent of Damage, Repairs may involve:

- Welding or patching

- Cleaning surfaces and air passages

- Reaming surfaces

- Replacing cores or cavities

- Installing new seats for inserts or core pins

- Repairing hot runner components

- Aligning plates and more

At Accel Precision, we understand that plastic mold repair and modification can be a complex process. That’s why we provide comprehensive services to help you get the job done quickly and efficiently.

We also provide preventative maintenance services to ensure your molds remain in optimal condition over time. We’ll inspect molds for signs of mould growth before beginning any work so that larger issues can be identified early on. With our help, you can rest assured that your injection molds will run smoothly throughout their lifetime.

Injection Mold Maintenance

Mold maintenance is essential for ensuring that injection molds run smoothly and perform optimally. It involves inspecting the molds for damage, such as visible mould, patches of mould, or nearby mould growth, as well as cleaning surfaces and air passages and replacing worn-out parts.

To ensure proper mold performance, it’s also important to check the venting systems and cooling lines for any blockages and flush them out if necessary.

Additionally, hot runner maintenance is key to avoiding costly repairs in the future. Finally, regular inspections should be conducted to identify indicator mould types that may signal underlying problems with the mold design. By taking these steps regularly, you can help keep your injection molds running efficiently while avoiding costly repairs down the line.

Should You Repair or Replace Your Injection Mold?

When you’re dealing with an aging injection mold, there are two options to consider: repair or replace.

Generally speaking, repairing a mold is more cost-effective if the damage is isolated and not extensive. Repairing the mold will also be faster and easier than replacing it.

However, if the damage is extensive or if the mould needs frequent repairs that are becoming costly, then replacing it may be the better option in the long run.

Before deciding whether to repair or replace your injection mold, it’s important to assess its current condition and any potential risks involved in continuing to use it.

With a thorough analysis of your current mould and an understanding of its capabilities, you can decide which route is best for your business.

Types of Molds We Work With

At Accel Precision Injection Molds, we specialize in several types of plastic injection molds, from complex designs and hot runners to simple single-cavity molds.

We have the experience and knowledge to meet the needs of any customer, regardless of the type of mould used. Our engineers are highly skilled in designing and building moulds that are optimized for performance and durability.